With rising energy costs and increasing demands for equipment availability, companies are seeking to balance operational performance with energy efficiency. When based on a preventive, data-driven approach, maintenance becomes a strategic lever for energy efficiency.

However, this data must be collected, cross-referenced and interpreted in a consistent manner. This is where SCADA, the cornerstone of modern operations, comes in. By centralising all the information from the field (consumption curves, temperatures, machine status, alerts) it makes it possible to anticipate deviations and optimise interventions.

With Panorama, the SCADA platform developed by CODRA, this cross-referenced intelligence takes on its full meaning: maintenance and energy are no longer silos, but two sides of the same sustainable performance strategy.

Preventive maintenance: the foundation of sustainable performance

Preventive maintenance aims to intervene before a breakdown occurs, based on the monitoring of key indicators (operating hours, vibration, temperature, pressure, etc.). By correlating this technical data with energy consumption, operators can identify abnormal deviations more quickly: a compressor that heats up abnormally or a motor that draws too much current becomes a warning signal.

Cross-referencing maintenance and energy data not only prevents breakdowns, but also reduces waste. Equipment that is under-performing or over-consuming energy is wasting energy and often a breakdown in the making.

Without centralised SCADA, this information remains scattered across sensors, controllers and specialised software. This fragmentation makes it impossible to obtain an overall view of performance.

With a SCADA platform such as Panorama E2, consumption, machine status and maintenance data are logged and linked in a single interface. Operators compare curves, adjust thresholds and plan interventions based on actual criticality. Closely linking maintenance and energy efficiency to a single, tool-based approach vents overconsumption and extends the life of assets.

Maintenance and energy efficiency: SCADA as the conductor of data

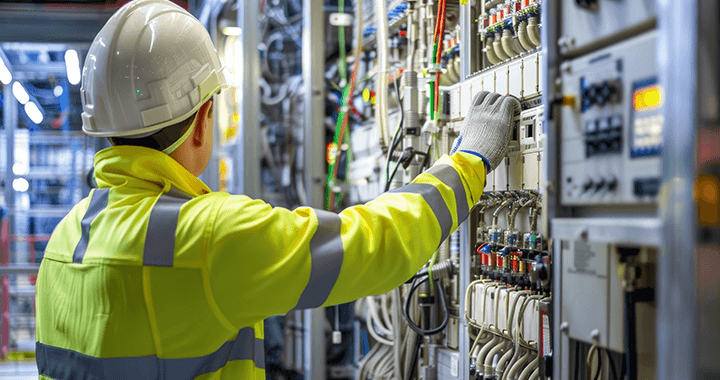

At the heart of the system, SCADA collects, structures and puts technical data into perspective. Energy consumption curves are superimposed on those for temperature, engine speed and pressure, allowing abnormal behaviour or occasional overconsumption to be observed.

Thanks to the HMI (Human Machine Interface), operators can view these correlations in real time via clear and dynamic synoptic diagrams. A temperature drift on an engine can thus be instantly compared to its increase in electricity consumption or its maintenance history. This contextualised cross-referencing of data becomes a valuable aid to decision-making.

In complex sites, Integrated SCADA Solution links safety and security, HVAC, processes and energy for a unified view. When teams combine maintenance and energy efficiency, alerts are prioritised according to their impact on consumption/availability, and interventions become targeted, measurable and traceable.

Panorama, a catalyst for eco-efficient maintenance

Thanks to its ability to cross-reference and log data from all systems, Panorama is establishing itself as the catalyst for eco-efficient operations.

The benefits are tangible:

- Reduced maintenance costs thanks to early detection of deviations.

- Optimisation of energy consumption through correlated analysis of machine status and load curves.

- Comprehensive, unified management thanks to an intuitive interface that links maintenance, energy and safety.

Beyond monitoring, Panorama becomes a decision-making tool. By leveraging historical data and IoT, the platform paves the way for condition-based maintenance and predictive energy strategies. This convergence places maintenance and energy efficiency at the heart of daily management and team KPIs.

Every piece of data collected (whether it’s a machine status, temperature or consumption curve) enriches the understanding of the site’s overall operation and enhances its energy efficiency.

Combining maintenance and energy efficiency is not limited to monitoring equipment: it is about understanding how they interact. By orchestrating data, SCADA, and Panorama in particular, brings connected operations to life, enabling them to anticipa s and evolve.

Thanks to the intelligent cross-referencing of data from the field, maintenance becomes a lever for energy optimisation, and energy becomes an indicator of equipment health. Panorama embodies this convergence, serving a more efficient, resilient and responsible industry.