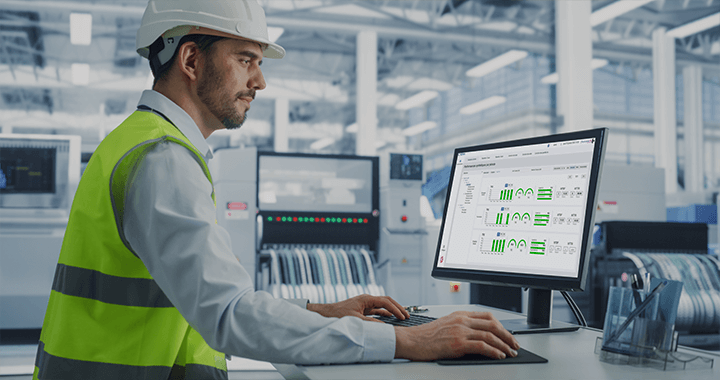

With competitiveness now based on efficiency and responsiveness, the integration of SCADA and process optimisation functions in the same platform has become crucial. To meet these requirements, we are launching Panorama COOX, the first MES product to be integrated into Panorama suite. With this new product, Panorama platform becomes a complete solution for Industry 4.0: now offering the very best of industrial SCADA and MES.

MES, the next stage in CODRA’s development

As part of our ongoing commitment to innovation and operational excellence, we are proud to present Panorama COOX, our new product dedicated to Manufacturing Execution Systems (MES). COOX has its origins in the strategic acquisition of Ordinal Software, a French software manufacturer renowned for its expertise in the MES field. Their flagship product, COOX, formed the basis for the development of Panorama COOX, enabling us to integrate proven know-how into our existing platform.

An MES, or Manufacturing Execution System, is a software solution designed to monitor and control production processes in real time. It optimises manufacturing operations by providing accurate, up-to-date information on production status, equipment performance and product quality. Panorama COOX is characterised by its modular and scalable approach, by initially offering COOX’s QPI (Quality & Performance Indicators) functions. Then PMT (Production Management & Traceability) functions will be the next stage of the evolution.

In this first version, Panorama COOX focuses on the key performance indicators (KPIs) that are essential for optimising production. These indicators include :

- OEE (Overall Equipment Effectiveness): This indicator measures the overall efficiency of equipment, taking into account downtime, production rates and product quality. It can be used to identify productivity losses and optimise manufacturing processes.

- OOE (Overall Operations Effectiveness): OOE assesses the overall performance of a production line, considering cycle times, downtime and scrap. It is a valuable tool for continuous improvement and strategic decision-making.

- TEEP (Total Effective Equipment Performance): This indicator focuses on the efficiency of individual pieces of equipment, making it possible to detect bottlenecks and optimise the use of resources.

- MTBF (Mean Time Between Failures): MTBF measures the mean time between two equipment failures. It is crucial for planning preventive maintenance and minimising production interruptions.

- MTTR (Mean Time To Repair) : MTTR measures the average time required to repair equipment after a breakdown. It helps to optimise maintenance processes and reduce downtime.

A product fully integrated into the Panorama Suite

Panorama COOX integrates seamlessly with our Panorama platform, benefiting from the same high standards of quality for which we are renowned. This integration offers several significant advantages over a traditional MES solution:

- Consistency and Quality Standards: All Panorama platform products share the same cybersecurity, scalability and adaptability standards. Panorama COOX benefits from annual updates, such as the latest PS2025, guaranteeing continuous improvement and optimum compatibility with the other components of the platform.

- Independence and flexibility: Although perfectly integrated, Panorama COOX can operate independently of the other products in the Panorama suite. This flexibility allows users to deploy the MES according to their specific needs, whilst benefiting from potential interactions with other elements of the platform.

- Interactions with other Panorama products: The integration of Panorama COOX with our SCADA, Historian and communication front-ends creates a cooperation that multiplies the capabilities of each component. For example :

- SCADA : By interfacing with our SCADA elements, Panorama COOX provides real-time SCADA of production operations. Operators can instantly visualise equipment performance and intervene quickly in the event of any drift. For example, if a piece of equipment shows signs of failure, SCADA can immediately alert the operator, while Panorama COOX provides detailed data on the potential impact on production.

- Historian : Panorama COOX collects and analyses production data over the long term. Users can identify trends and anomalies, such as increased downtime or reduced quality, and take corrective action based on accurate historical data.

- Communication Front-End: Thanks to our communication front-end, Panorama COOX can exchange information with various third-party systems and equipment, ensuring maximum interoperability. For example, Panorama COOX can receive data from external sensors to enrich its analyses or send instructions to production equipment to optimise processes in real time.

- Adaptability and Interoperability: Designed to meet the needs of various industrial sectors, Panorama COOX offers exceptional adaptability. Whether in the automotive, aerospace, pharmaceutical or food industries, our MES solution adapts to the specific needs of each sector, guaranteeing maximum optimisation of production processes.

In conclusion, Panorama COOX represents a major advance in the field of MES, offering an integrated, flexible and scalable solution for the SCADA and optimisation of production processes. Often separated into standalone tools, these subjects are nonetheless closely connected: a production process cannot be optimised without its installations being in perfect working order. With the Panorama Suite, you will have the foundation for smarter, more efficient production.