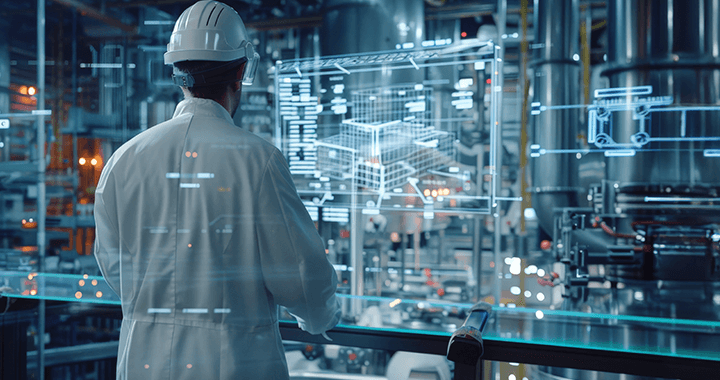

Industry 4.0 is much more than just a buzzword; it refers to a concrete transformation of industrial processes, made possible by the interconnection of systems and the digitalisation of flows. Among the pillars of this change, intelligent SCADA is emerging as a key factor in the management, optimisation and reliability of industrial sites. How are these tools transforming everyday life in factories? What Industry 4.0 use cases illustrate this change? An overview of the practices that are shaping the factory of the future.

Intelligent SCADA and Industry 4.0: a new operational dynamic

Intelligent SCADA is based on an integrated flow logic, ranging from data collection to the immediate implementation of corrective actions. Sensors installed on production lines, in technical equipment or within infrastructure provide key information such as temperature, vibration, energy consumption, speed, pressure, etc.

This data is aggregated within SCADA platforms capable of triggering automatic actions. For example, a system can adjust the temperature of an oven or change the speed of an assembly line without human intervention. This real-time control makes it possible to anticipate deviations, reduce waste and ensure continuity of production. Industry 4.0 stands out here for its ability to integrate these control mechanisms as close as possible to the field, making factories more responsive, more reliable and better controlled.

Technologies for industrial performance

Intelligent SCADA relies on a set of complementary technological building blocks which, once interconnected, enable optimised management of industrial processes.

- Digital twins: these virtual models faithfully reproduce physical equipment or complex systems. They make it possible to simulate scenarios, test modifications or predict behaviour without disrupting actual production. They thus reduce prototyping costs and anticipate failures.

- MES ( Manufacturing Execution System ): this system connects production machines to enterprise software (ERP), ensuring real-time traceability of operations. It centralises execution data, synchronises production orders and adjusts planning according to actual constraints on the ground.

- Real-time flow analysis: this optimises production cycles, identifies micro-stops or drops in yield, and triggers targeted adjustments. Quality control becomes proactive, with vision systems that continuously inspect 100% of products.

- Industrial BIM: initially designed for building management, a solution such as BIM for Operations is now finding its place in industrial sites. By integrating infrastructure, technical networks and operational data, it facilitates maintenance, improves energy management and supports more sustainable operations.

Concrete use cases of Industry 4.0 for an optimised value chain

From predictive maintenance to overall reliability

Thanks to intelligent monitoring, maintenance is no longer reactive, but preventive. Sensors continuously measure weak signals of wear or malfunction. A change in vibration or an unusual rise in temperature can signal a future breakdown. Operators are alerted early enough to intervene without interrupting production.

Large-scale customised production

One of the key features of Industry 4.0 is the ability to produce customised batches with the efficiency of mass production. Thanks to RFID technology, each product carries its own manufacturing instructions. Machines adapt their settings with each pass without the need for manual reconfiguration.

An agile and connected supply chain

Intelligent SCADA extends to the entire supply chain. With real-time visibility of inventory, transport flows and supplier lead times, industrial sites can dynamically adjust their planning. A delivery delay triggers a reallocation of resources, while a peak in demand can lead to an automatic increase in production speed.

In the context of Industry 4.0, intelligent monitoring acts as a real performance catalyst. By connecting equipment, systems and operators around reliable, actionable data, it enables manufacturers to go beyond automation towards flexible, optimised and sustainable production. Its gradual deployment is shaping the contours of a resilient industry, capable of absorbing shocks, innovating continuously and adapting to market demands in real time.