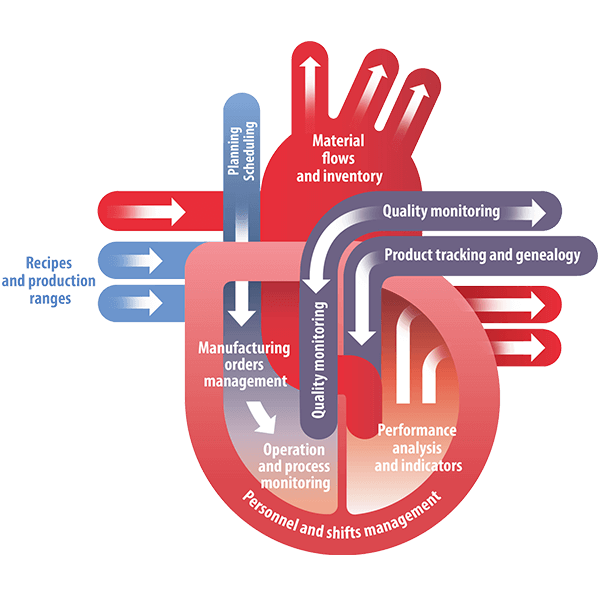

The heart of smart factory

MANUFACTURING EXECUTION SYSTEM

What is MES software ?

By collecting all production data in real time, MES (Manufacturing Execution System) software makes it possible to control and track production more effectively. It provides all the necessary information and instructions to managers and operators so that they can ensure the smooth running of production, right from the release of a manufacturing order through to the finished product. The software tracks all the information needed to meet quality requirements and identify sources of production optimization. As a result, it plays a major role in the continuous improvement of production.

- RESOURCE MANAGEMENT

- SCHEDULING

- PRODUCT AND BATCH ROUTING

- DOCUMENT MANAGEMENT

- DATA COLLECTION AND ACQUISITION

- PERSONNEL MANAGEMENT

- QUALITY MANAGEMENT

- PROCESS MANAGEMENT

- MAINTENANCE MANAGEMENT

- PRODUCT TRACEABILITY AND GENEALOGY

- PERFORMANCE ANALYSIS

Work by ISA-95 further led to a more detailed analysis of the services that an MES solution must deliver and to underline the systems perspective. While the different MES functions can be implemented incrementally, they are not independent of each other and must share a large amount of information.

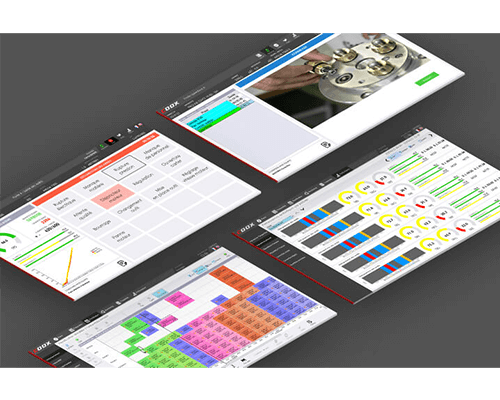

A response adapted to each industrial problem

What kind of information will the MES provide?

A few simple cases, drawn from a variety of standpoints, will help to understand the contribution of an MES in more practical terms.

I analyse and improve my performance

How are my lines scoring on OEE (Overall Equipment Efficiency)? What are the reasons behind the performance differentials, the quality rates or a prevalent type of production stoppage? How many productivity points are we losing on line 4 because of the set-ups? Does the morning shift perform better than the afternoon shift? And what’s the reason?

I optimise my planning

Are we meeting deadlines despite a maintenance outage on one of the lines?

Is it possible to run the promotion before or at the same time as the delivery scheduled for tomorrow morning? Can we still meet the delivery date for order CC5678 despite the delay incurred on the line due to the breakdown?

I analyse the quality of my production

A whole batch of mechanical parts has been rejected by our customer. Were we not able to ensure that the dimensions were correct before delivery?

Had the equipment used for product preparation on 13/9 been cleaned?

Does my production comply with the latest regulations?

I improve the traceability of my production

What was the exact dosage of sugar in batch LL876 of organic product?

Which supplier provided the colorant used in this yoghurt refused by the quality control?

Cold room n°3 was under maintenance, could this have had an impact on the production target?

.

Ensuring digital continuity

Where does MES fit into the Information System?

While the primary role of SCADA (Supervisory Control and Data Acquisition) software is to enable communication between PLCs and plant equipment to enhance control of production, the primary role of management software packages (in particular ERP – Enterprise Resource Planning) is to manage resources and help the manufacturer with the organisational aspects.

For a long time, there was a large space in between, with a lot of room – in fact a major need – for specific developments to ‘bridge the gap’ and make the two environments connect.

MES software equates to the missing link, ensuring continuity between the ERP data and operations on the factory floor.

To accomplish this, it centralises and orchestrates all the production data and provides the manufacturer with relevant and timely key data so that they can be reactive to expectations and developments in their marketplace, as well as keeping up with all regulatory requirements.

The MES software offers the industrialist more flexibility and agility, so they can stay competitive, control their process and achieve truly challenging levels of industrial performance.More broadly, manufacturers will benefit from improvements in the management of their flows, inventory and processes, and as a result achieve gains in quality, efficiency and productivity.

DO YOU HAVE A MES PROJECT?