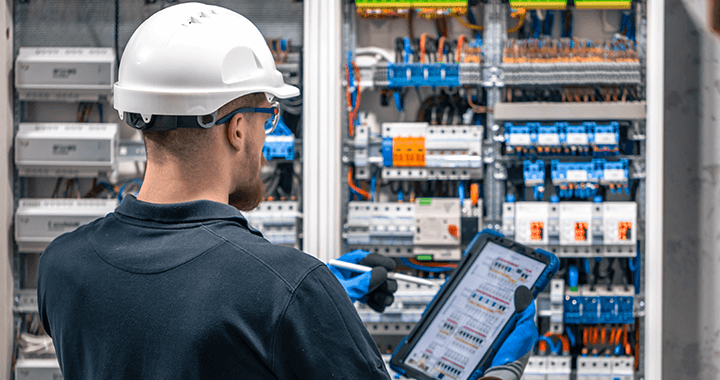

Manufactured by Siemens, SIMATIC S7 PLCs are essential in the field of SCADA. In many sectors, SCADA applications need to communicate with these PLCs. What are the possible solutions? CODRA offers you a range of possibilities.

Indirect dialogue with Siemens PLCs

The PLCs in the SIMATIC S7 range are industrial programmable controllers. They enable real-time SCADA of production processes, providing accurate, up-to-date data about the status of machines and processes.

S7Comm, short for S7 Communication, is also known as Industrial Ethernet or, Profinet. This communication protocol was developed by Siemens for communications between its PLCs in the SIMATIC S7 range and with SCADA systems. As the protocol is proprietary, a SCADA application may not be able to communicate directly with these Siemens PLCs.

Indirect communications is often implemented using an OPC (Open Platform Communications) server. This server acts as a communications gateway: the S7Comm communications protocol is “translated” into an OPC format that the SCADA application can understand.

This method of communication works very well, and is a well-used standard in the OT industry. However, it does have a few drawbacks:

- High cost : an additional server is often expensive for an installation, particularly for smaller installations.

- Complexity: the implementation of an OPC server is a furthercost in terms of configuration, deployment and maintenance.

- Security: a new server requires accurate and thorough configuration, in order to avoid increasing security risks (exposure) or operational risks (failure).

The Panorama solution: direct communication

Panorama natively integrates the S7Comm protocol, which means it can communicate directly with many SIMATIC S7 PLCs, and is compatible with the following PLC models: S7-200, S7-300, S7-400, S7-1200 and S7-1500.

Depending on the model, there are two direct communications modes:

- PUT/GET: Panorama uses a specific, direct address (e.g. DB001/S7_BIT:0), which reads and writes data directly to the designated database, known as DataBlock or Tagblock in the Siemens PLC.

- Symbolic adressing: Panorama explores a directory of database addresses, that are symbolic, i.e. they refer to real-world information (e.g. “TemperatureSensor”).

Of the two methods, symbolic addressing is the simpler to use. Symbolic addressing makes data acquisition and PLC control more intuitive, resulting in fewer errors during operation. Unfortunately, older SIMATIC S7 PLCs can only communicate via PUT/GET. More modern PLCs, on the other hand, can use both methods. We recommend that you always use symbolic addressing.

Direct communications has several substantial advantages:

- Reduced costs: investment in OPC servers is no longer necessary, which means lower maintenance costs.

- Simplified configuration: configuration is validated more quickly, saving time for operators and integrators.

- Improved security: the exposure surface is reduced, and the S7Comm protocol has numerous security mechanisms (authentication, logging, etc.).

- Increased reliability: fewer intermediaries means fewer potential issues, and also fewer communication errors.

Indirect dialogue via an OPC server is a tried and tested standard, but the prevalence of SIMATIC S7 PLCs makes direct communications essential. Direct compatibility with S7Comm, such as that offered by Panorama, simplifies configuration, reduces costs, improves security and reliability, and optimises performance. The continued integration of advanced technologies such as S7Comm promises to transform industrial automation, delivering ever more efficient and secure solutions.