10% water savings by 2030: this is one of the objectives of the Water Plan published in 2023 by the French government. Among the 53 measures announced, the food industry will have to fit meters with remote transmission of the volumes of water withdrawn, with the aim of better managing the resource.

Water is one of the major themes at CFIA Rennes 2024, with several conferences on the subject and a host of experts in attendance. This gathering of more than 1,700 players in the food industry is the ideal opportunity to work together to meet the challenge of reducing water consumption.

Codra will be present in Hall 6 – stand D21 to help you meet the major challenges facing your industrial facilities.

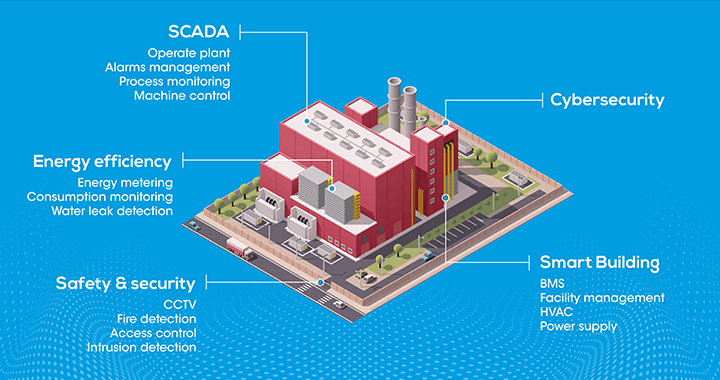

How can our SCADA and MES software enable you to better manage your resources while optimising your production processes?

Meet teams Codra

from 12 to 14 March 2024

At Parc Expo of Rennes

stand CODRA D21 – Hall 6

Controlled water management with the Panorama platform

Remote water metering will soon be compulsory for industrial facilities, and the food industry is no exception. Codra is making a monitoring and reporting tool available to players in the sector, to help them collect data and monitor and analyse water consumption. Data from sensors, loggers and PLCs is fed into the Panorama platform.

A genuine remote management tool, Panorama also gives you an overall view of the installations at your various remote sites. Our robust, secure solution enables you to monitor the water consumption of your various industrial processes: washing, cutting, mixing, etc. The Panorama application enables you to detect potential leaks to ensure continuous use of the resource.

Optimise your water consumption, save money and meet the challenges of the ecological transition.

Complementary solutions for industrial performance

As well as managing your water consumption, Codra can help you achieve your industrial performance objectives. SCADA, Data Historian, Front-end communication and MES, all our solutions meet your various operational needs.

In terms of process optimisation, our Historian solution allows you, for example, to consult detailed graphs and reports. Panorama software interfaces with your databases to bring up key values and highlight performance indicators. You can analyse your production, quality and maintenance costs.

These analyses will help you save time, improve the quality of your work and better organise the various stages of production.

Reducing your energy consumption is also one of your daily challenges.

Collecting, processing and archiving your data in Panorama means you can monitor all the utilities (electricity, gas, compressed air, water, etc.) required to keep your industrial processes running smoothly. From the SCADA application, you can analyse peaks in consumption and refer to monthly reports, for example, to make the best decisions.

To meet increasingly stringent regulations in real time, control your processes and improve your productivity, we provide you with the tools you need to monitor your production effectively, while guaranteeing impeccable quality and traceability. By collecting all your production data in real time, our MES enables you to optimise the monitoring and management of your industrial processes.

All the MES functions are available on a single integrated, modular platform: production and work order scheduling, execution of automated operations and digitisation of manual operations with operator guidance, process and product traceability, performance indicators (TRS) and analysis dashboards.

The genealogy of materials and products is an essential aspect of traceability in the food industry today. Starting with a batch of finished product, it immediately identifies the batches of raw materials used in its manufacture (ascending genealogy), enabling the potential origin of a problem to be quickly traced. Conversely, starting from a batch of raw material analysed as defective, it immediately identifies the batches of finished products that have used it (top-down genealogy), making it possible to warn the customers actually concerned of a potential problem and, if necessary, to carry out a controlled withdrawal of the perimeter, minimising the economic impact and in terms of image for the company.